Laser Processing of Transparent Materials

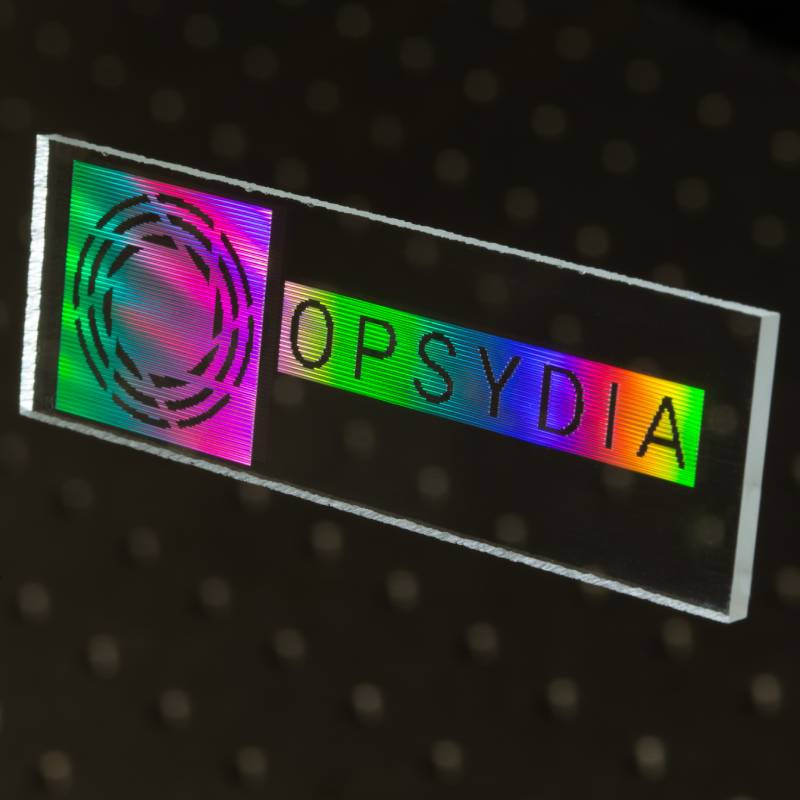

The benefits of Opsydia’s breakthrough technology platform for diamond security also extends to other transparent materials. Laser processing can be performed over large volumes to create features inside transparent materials, including polymers, plastics and glass. The ultra high resolution system ensures that features can even be created inside thin films. The optical properties of these features can be carefully designed to give visual effects in everyday lighting conditions.

Would you like to discuss the applications of Opsydia technology for your transparent materials?

Secure and Resilient

Opsydia systems are designed with security at their core; encryption secures designs & prevents counterfeiting and fraud. By embedding within the material, the visual effect is ensured by the integrity of the substrate. Features created inside transparent materials are wear-resistant and impossible to remove without destroying the product itself.

Microscopic, high resolution features create macroscopic visual effects. This microscopic substructure can be customised to create unique fingerprints and other covert security features that are inherent in the material, providing further layers of protection.

Our Capabilities

Features have been created in perspex, polycarbonate, polypropylene, glasses and many other materials. The images below show an example of a diffractive feature inside a plastic sample. Serial numbers, holograms, overt aesthetic features and covert security features are all possible in a wide range of materials. Contact us to discuss your unique requirements.