Advantages of Adaptive Optics

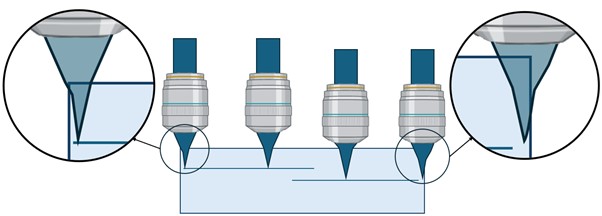

Direct laser writing of waveguides has always faced two discrete challenges which are now overcome by the use of adaptive optics, namely “writing at different depths” and “writing to the edge of the material”.

Writing a high-quality optical waveguide in a transparent material is conceptually simple. However, the quality of the waveguide critically depends on the ability to overcome aberrations encountered by the writing laser beam. For a given depth in a material, many users will just try to optimize the waveguide in a trial and error way. This may yield somewhat acceptable results since the aberrations are the same for all points at that given depth. When users want to write waveguides at multiple depths, for example in an array, the depth effects differ significantly. Using adaptive optics to overcome depth dependent aberrations removes this consideration and makes it possible to write at different depths, change depths for a single waveguide and to do so while writing truly optimized waveguides.

Writing to the edge of a material presents a unique challenge for waveguide development. Historically, most directly written waveguides simply stop short of the edge and the user then polishes back the surface facet to the point where the waveguide is exposed. This undesirable step has been necessary because users could not overcomes the complex aberrations encountered as the laser beam approaches the edge of the sample. This problem has been overcome with a technique developed at the University of Oxford and commercialized by Opsydia. As it is now possible to write directly to the edge, even at different depths, the user no longer needs to have any additional post processing steps. Direct laser writing of waveguides is FINALLY Direct.

Note in this picture that the edge effect is present at more shallow depths, but much more pronounced at greater depths. To overcome this at all, and especially dynamically, adaptive optics are a must.

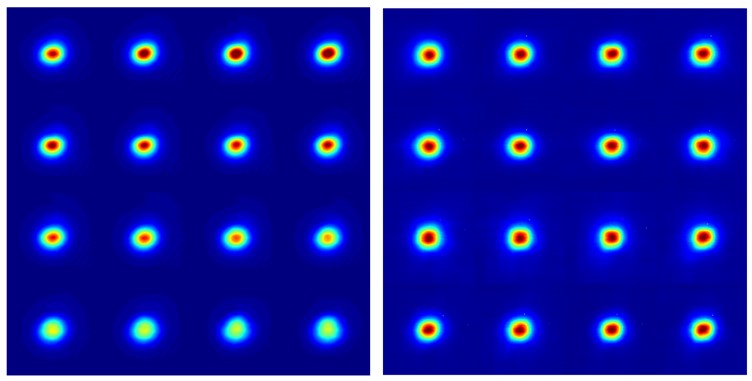

In the following picture, we can see the impact of the edge correction quite clearly. In each cases we show a 4×4 array of waveguides. For the array on the left, the depth correction function is turned on, but the edge correction function is not. For the array on the right, both depth correction and edge correction are turned on. The difference is striking, highlighting the need for adaptive optics in both situations.

The Advantages

"Better" Beam

“Better” beam parameters at the target area. What exactly “better” means depends on what the user cares about, but may mean smaller, more symmetric beams, etc.

Dynamic Writing Depth

The ability to write at different depths in a material is key to exploiting real estate and delivering greater waveguide densities. As the amount of aberration encountered changes with depth, it is critical to be able to correct for this dynamicallly.

Writing to the Edge

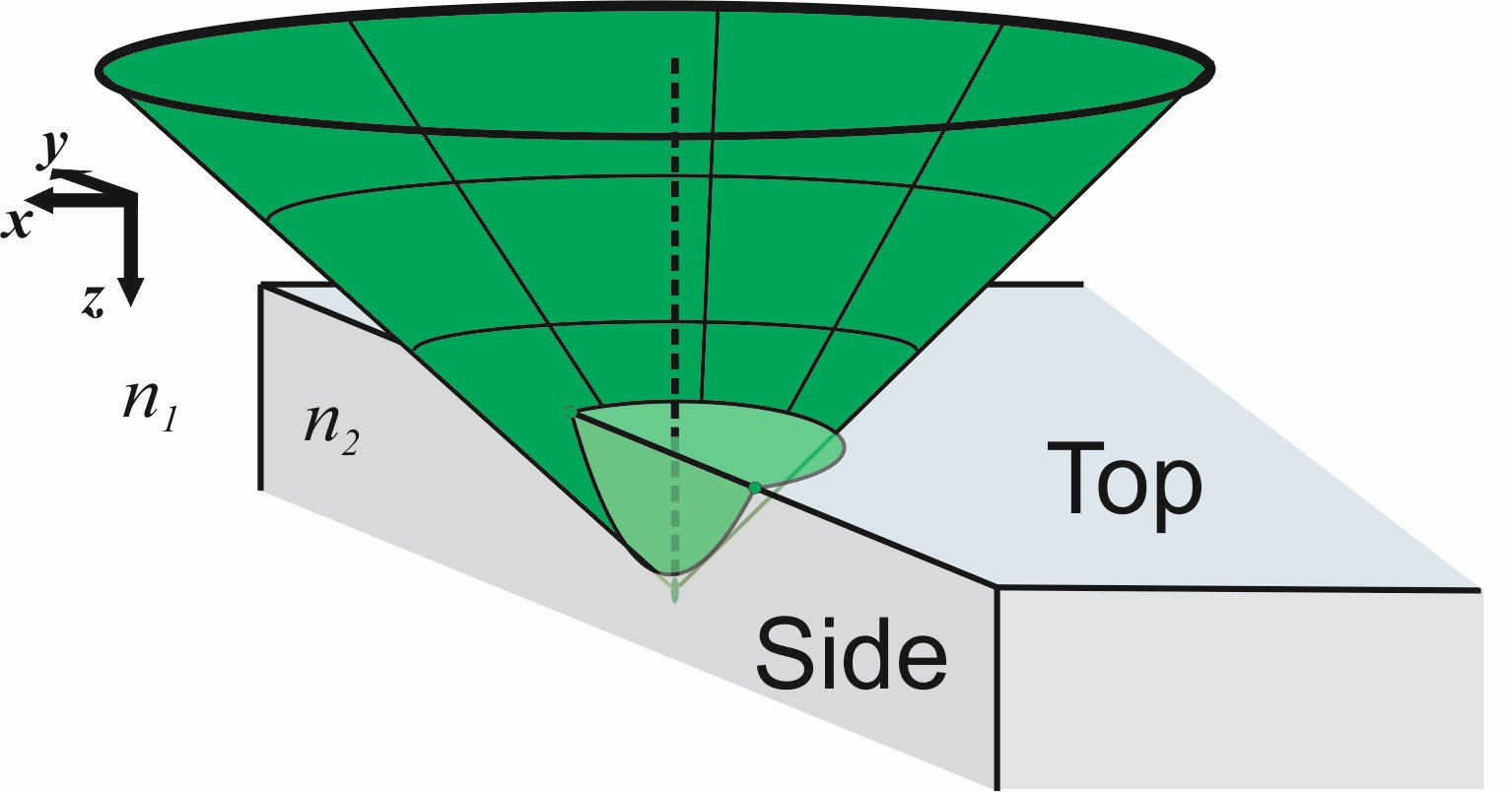

As the laser beam focuses deeper into the material, the aberrations encountered increase dramatically. The situation is more complicated when the focussing cone is at the edge of the material. Part of the beam cone passes through the surface of the material, whereas part passes through the side face (see Fig 1). This presents a special challenge and we must adapt for the beam dynamically as it reaches the edge of the material, selecting the appropriate corrections to allow us to maintain optimal waveguide writing.

The adaptive optics approach can overcome this and this approach is the subject of a patent licensed by Oxford University to Opsydia.

Figure 1: Focused laser beam is shown partly inside the material and partly outside the material. This special case can present difficulties for the material processing which can be overcome by the use of adaptive optics.

P. S. Salter and M. J. Booth, “Focussing over the edge: adaptive subsurface laser fabrication up to the sample face,” Opt. Express 20, 19978-19989 (2012)

Available on all devices

Capable of melee inscriptions

Suitable for coloured gemstones

High capacity (100k+ stones p/a)

Encryption secure IDs

Automation and machine vision

Remote service and diagnostics

Integrates with blockchain traceability solutions

Integrates with factory IM systems

Multiple stone loading

Available on all devices

Capable of melee inscriptions

Suitable for coloured gemstones

High capacity (100k+ stones p/a)

Encryption secure IDs

Automation and machine vision

Remote service and diagnostics

Integrates with blockchain traceability solutions

Integrates with factory IM systems

Multiple stone loading

“Adaptive optics is essential to maintain a precise laser focus inside the materials. This is particularly important when creating the high performance devices that our customers require.”

Prof. Patrick Salter

Founder & Director, Opsydia

Latest News

Founding Scientist, Prof Martin Booth at CLEO Europe 2025

Founding Scientist, Prof Martin Booth at CLEO Europe 2025

Prof. Patrick Salter presents at CLEO Europe 2025

Founding Scientist Prof. Patrick Salter presents at CLEO Europe 2025.

Contact Us

To find out more about the Opsydia Systems or to discuss a trial or demonstration, please speak to a member of our team.